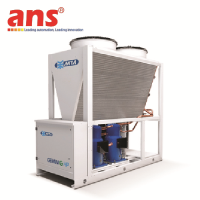

Air cooled chillers ARIES N MTA S.P.A Vietnam

Price: Contact

Brand: MTA S.P.A

Category: Process cooling solutions MTA S.P.A

Supplier: ansvietnam

Origin: Italy

Air cooled chillers ARIES N MTA S.P.A Vietnam

Air cooled liquid chillers featuring inverter reciprocating compressors with propane.

Nominal cooling capacity 232 – 448 kW

THE NATURAL ANSWER TO YOUR COOLING NEEDS

iASN air-cooled industrial process chillers are designed specifically to deliver absolute dependability for the most demanding industrial applications.

MTA is fully committed to supporting the green transition of energy systems towards an all-inclusive solution. Advanced technologies and the application of natural refrigerant R290, with zero environmental impact, are combined in ARIES N chillers, offering a long-term sustainable solution.

The chiller features all the main hydraulic and mechanical components integrated inside the unit, as standard.

An extensive range of options, coupled with wide operating limits, confirm iASN as the perfect plug & play solution, the ideal fit in a variety of process cooling applications.

Technical features

| Mode | Compressors | Refrigerant | Heat exchanger | Fan |

|

|

R290 |  |

|

Standard features

• Natural refrigerant R290 – Propane;

• 2 reciprocating compressors in 2 circuits with 1+i configuration;

• Compressor crankcase heater and phase-monitor;

• Integral enclosure and acoustic insulation on compressor compartment;

• Brazed plate evaporator heat exchanger;

• Microchannel condenser coils;

• Axial EC brushless fans complete with protective grids and die-cast aluminium airfoil blade profiles;

• Electronic expansion valves;

• Electrical cabinet protection rating IP54;

• Electronic microprocessor controller with touch screen user display;

• Modbus RS485 serial output for connection to supervision systems;

• IN/OUT compressor valves;

• “Victaulic” hydraulic connections kit (supplied for each unit);

• Extensive tests and verifications performed in the factory;

• Non-freezing oil and refrigerant charge for configurations up to 12 kg of refrigerant volume.

Options

• MWT version (down to -10 °C outlet water temperature);

• Low ambient temperature option (down to -20 °C);

• SingleXtwin water pumps with low (P2)Xmedium head pressure (P3);

• Water accumulation tank;

• Anti-freeze protection heaters for heat exchangers, pump/s and water accumulation tank (if installed);

• Partial heat recovery;

• Energy meter;

• Protective epoxy coating for condenser coils, for installation in aggressive environments;

• Metal mesh filters for condenser coil protection.

Kits

• Antivibration mounts;

• Metal mesh filters for condenser coil protection;

• Modularity kit (master/slave from 3 to 4 units).