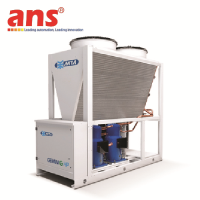

Refrigeration air dryers DE-X MTA S.P.A Vietnam

Price: Contact

Brand: MTA S.P.A

Category: Compressed air & gas treatment MTA S.P.A

Supplier: ansvietnam

Origin: Italy

Refrigeration air dryers DE-X MTA S.P.A Vietnam

Refrigeration Dryers

Air flow 0,35 – 35 m³/min

DE-X refrigeration dryers offer accurate dew point control in an easy-to-use package with very wide operating parameters and a strong focus on reducing overall global impacts. Unique features and patented technologies ensure the requirements of individual industrial applications are fully catered for.

| Mode | Compressors | Refrigerant | Heat exchanger | Fan |

|

- | R513A; R410A | - | - |

Benefits:

- Market leading pressure drops, on average below 0,12 bar, ensuring significant energy savings.

- Environmentally friendly low Global Warming Potential (GWP) refrigerant R513A on DE-X 003-090, with a GWP of only 573.

- Unique patented 3-in-1 X-MODULE heat exchanger, designed by MTA.

- Always operates in all conditions, with extensive air inlet temperature, ambient temperature and maximum pressure limits.

- High reliability, with field proven technologies and premium components.

- Easy to install thanks to compact dimensions, a single wired power source and full frontal access.

- Easy to use: intuitive microprocessor, avoids field adjustment requirements, low maintenance needs.

- Multiple condensate drain configurations covering every User need.

- Accurate dew point control across the full 0-100% load spectrum, with quick reactions in response to sudden peaks.

- Low Load Function (LLF) protects against freezing, simplifies seasonal adjustment needs, allows stand-by savings at low ambient temperatures.

- Industry 4.0 ready, with multiple remote connectivity options.

- Extensive individual factory testing (operating sequences, refrigerant leakages, safety devices, electrical safety).

Technical specifications:

- Robust heavy-duty housing with galvanized steel panels and RAL7035 epoxy powder coated painting.

- Environmentally friendly refrigerant (R513A for DE-X 004-090, R410A for DE-X 120-350).

- Reciprocating (DE-X 003-090), rotary (DE-X 120-140) and scroll (DE-X 180-350) compressors.

- Hot gas expansion valve.

- Calibrated capillary tube.

- Compact and robust X-MODULE 3-in-1 aluminium heat exchanger, with pre-formed close-fit high density polystyrene insulation.

- Low Load Function (LLF) compressor management.

- Air-cooled condenser with tubeless (DE-X 003-027) and finned coil (DE-X 032-350) configurations; standard protective coating on DE-X 003-027.

- Axial fan.

- Microprocessor controller with multi-icon display, numerical dew point readout, multiple alarms with alarm history function, maintenance scheduling and full password protected programmability.

- General alarm volt free contact.

- Remote on/off contact.

- Automatic restart.

- Configurations with either a programmable timed drain, a Smart zero-loss electronic drain (DE-X 003-060) or a sensor activated zero-loss electronic drain with a visual alarm signal (and a remote alarm signal on DE-X 180-350).

- Drainage outlet with protective mesh filter and manual shut-off valve.

- Maximum air inlet temperature: 70°C (DE-X 003-090); 65°C (DE-X 120-140).

- Maximum ambient temperature: 50°C (48°C for DE-X 290, 46°C for DE-X 350).

- Maximum working pressure: 16barg (14barg for DE-X 180-350).

- Electrical protection rating: IP22.

Accessories and kits:

- RS485 serial interface.

- Compressed air by-pass kit (DE-X 003-240).

- Condensate drain conversion kit.

- Protective condenser coating (DE-X 032-350).

- Water-cooled configurations (on request).

- Special voltages (on request).

- Special packing.