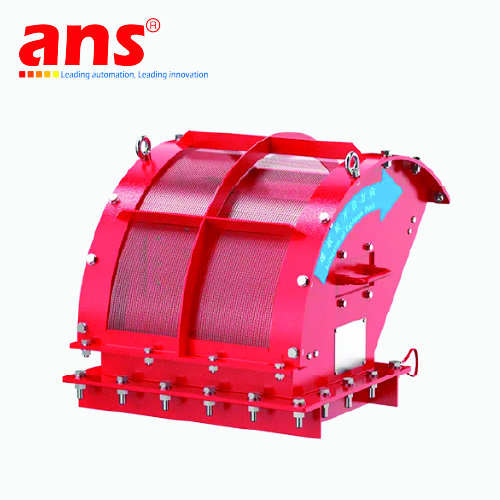

Flameless venting device FEV-S-230X305 Basco Vietnam

Price: Contact

Brand: Basco

Category: Vapour Control

Supplier: ansvietnam

Origin: China

Flameless venting device FEV-S-230X305 Basco Vietnam

- Material: Carbon Steel Housing + Stainless Steel Filter

- Flameless relief device requires no special maintenance

- Flange connection can be customized

- A variety of flameless structures are available to meet the needs of different working conditions, such as: round, rectangular, square.

Product Overview

Can be used for protection against indoor or outdoor dust explosions, with no other running costs, easy installation and no need to install pressure relief conduits. It consists at least of a rupture plate and a flame arresting element.

-

Principle of operation

When an explosion occurs, the rupture plate opens, and when the flame passes through the mesh flame arresting element, the flame arresting element exchanges heat with the flame, rapidly cools down the high temperature flame, releases pressure and smoke, ensures that the flame is not propagated to avoid causing a secondary explosion or multiple explosions, and at the same time, the pressure wave or noise generated by the explosion will be reduced to a lower level.

-

Use and Maintenance

The flameless relief device is a passive, mechanical principle of action and requires no commissioning after installation.

It is recommended that the safety zone be defined according to the diagram below to ensure that no additional injuries are caused in the event of a dust explosion. Where: d1 > 1m (for equipment buildings); d2 > 2.5m (for personnel).

Regularly inspect the surface of the flameless relief device for accumulation of dust, snow, ice, or the presence of other buildup that interferes with the proper functioning of the relief device, and if so, remove it by appropriate means.

Regularly inspect the pressure relief element (bursting plate) for breakage, the inspection period should be no more than 1 month.

Regularly check the fire extinguishing element for blockage, the inspection period should be no more than 1 week.

If the pressure relief element is found to be broken, it should be shut down and replaced in time. During the replacement process, it should be ensured that there is no residual dust or effective ignition source.

If there is an optional alarm output, please check the wiring regularly for any abnormality, and the inspection cycle is recommended to be no more than 1 week.

If the flameless relief device is found to be leaking powder or air, the rupture plate may have burst due to overpressure, which can be initially checked through the inspection port.