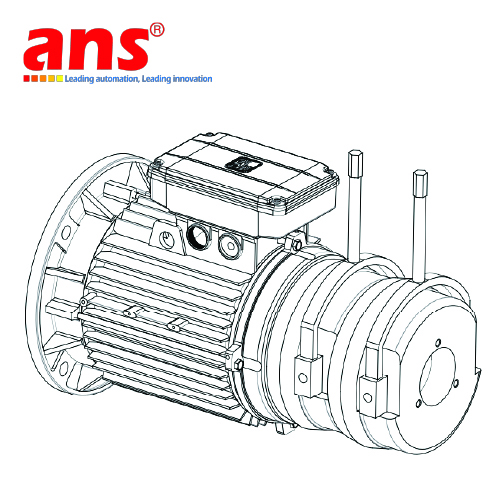

BMBM SERIES M.G.M. Motori Elettrici S.p.A.Vietnam

Price: Contact

Brand: M.G.M. Motori Elettrici S.p.A.

Category: electric brake motors

Supplier: ansvietnam

Origin: Italy

BMBM SERIES M.G.M. Motori Elettrici S.p.A. Vietnam

BMBM series motors are designed for intermittent duty S3 25% (see technical data). BMBMX series motors for intermittent duty S3 40% are

also available. Consist of asynchronous three phase brake motors with twin DC brakes working independently of each other, starting from 63 up to 315 frame sizes and power range from 0.08 kW up to 132 kW. BMBM series main feature is a very high reliability in those lifting applications where there are high demands of safety and silence. For these reasons BMBM series motors are particularly suitable to be used in TV-cine studios and theatre stages

The motor brakes in case of power supply failure.

The braking action is always secured through a very quick and precise stop assuring a safe and a prompt stop in case of unintentional power supply failure. The brake torque remains the same in both directions of rotation and the braking action occurs without shaft axial sliding. The brake components and assembly are designed with special features to be noiseless during stops. The manual brake release is made up of two levers (one for each brake) so to avoid unwanted starts. It’s possible to release the brakes just using one hand.

The two brakes are supplied through independent rectifiers which are positioned in the terminal box. Rectifiers are provided with over-voltage

protection device. It’s possible to have two types of wirings connection to the rectifier for each brake, in relation to the intervention time

required. All BMBM series motors can be driven by inverters. On request, it’s possible to have the motor with a built-in encoder or to have the motor ready for the encoder to be easily fitted at customer’s place. The brake disc friction material is asbestos free and the brake lining has a high friction factor and is long-lasting. The standard winding insulation class is F. Class H is available upon request. Motor construction type is Totally Enclosed Not Ventilated (TENV) with IP 54 enclosure rating (IP 55 and external cooling are available upon request). BMBM series motors tolerate a high overload level and being not self-cooled have to be used on intermittent duty only

| 2 pole - 3000 RPM | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 63 A2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 63 B2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 63 C2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 71 A2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 71 B2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 71 C2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 80 A2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 80 B2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 90 SA2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 90 LA2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 100 LA2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 112 MB2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 112 MC2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 132 SA2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 132 SB2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 132 MA2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 132 MB2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 160 MA2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 160 MB2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 160 LA2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 180 LA2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 200 LA2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 200 LB2 |

| 4 pole - 1500 RPM | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 63 A4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 63 B4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 63 C4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 63 D4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 71 A4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 71 B4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 71 C4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 71 D4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 80 A4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 80 B4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 80 C4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 90 SA4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 90 LA4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 90 LB4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 90 LC4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 100 LA4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 100 LB4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 112 MB4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 112 MC4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 132 SB4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 132 MA4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 132 MB4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 132 MC4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 160 MA4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 160 MB4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 160 LA4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 180 LA4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 180 LB4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 200 LB4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 225 S4 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 225 M4 |

| 6 pole - 1000 RPM | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 63 C6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 63 D6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 71 A6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 71 B6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 80 A6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 80 B6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 90 SA6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 90 LA6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 90 LB6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 100 LA6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 100 LB6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 112 MB6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 132 SB6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 132 MA6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 132 MB6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 160 MB6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 160 LA6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 160 LB6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 180 LB6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 200 LA6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 200 LB6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 225 M6 |

| 8 pole - 750 RPM | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 63 D8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 71 A8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 71 B8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 80 A8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 80 B8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 90 SA8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 90 LA8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 90 LB8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 100 LA8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 100 LB8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 112 MB8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 132 SB8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 132 MB8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 160 MA8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 160 MB8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 160 LA8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 180 LB8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 200 LA8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BMBM 225 M8 |

BMBM series includes three-phase asynchronous brake motors with twin DC brakes working independently of each other, starting from 63 up to 315 frame sizes and power range from 0.08 kW up to 132 kW. BMBM series motors are designed for intermittent duty S3 25% (see technical data). BMBMX series electric brake motors for intermittent duty S3 40% are also available.

BMBM series main feature is a very high reliability in those lifting applications where there are high demands of safety and silence. For these reasons BMBM series motors are particularly suitable to be used in TV-cine studios and theatre stages. The motor brakes in case of power supply failure. The braking action is always secured through a very quick and precise stop assuring a safe and a prompt stop in case of unintentional power supply failure. The brake torque remains the same in both directions of rotation and the braking action occurs without shaft axial sliding. The brake components and assembly are designed with special features to be noiseless during stops.

The manual brake release is made up of two levers (one for each brake) so to avoid unwanted starts.

It’s possible to release the brakes just using one hand. The two brakes are supplied through independent rectifiers which are positioned in the terminal box.