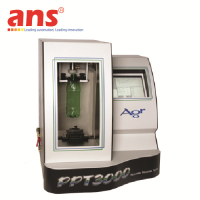

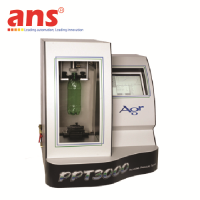

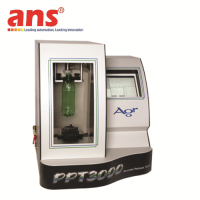

Packaging Pressure Tester PPT4000 AGR Vietnam

Price: Contact

Brand: AGR International Vietnam

Category: Tester

Supplier: ansvietnam

Origin: USA

Packaging Pressure Tester PPT4000 AGR Vietnam

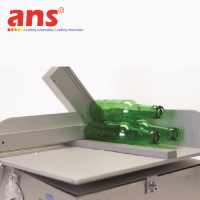

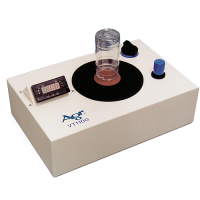

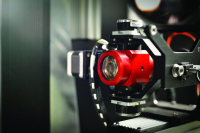

The PPT4000™ Packaging Pressure Tester offers high-resolution pressure and volume expansion testing for plastic and related containers, with the versatility to perform a number of industry standard and custom test profiles. The PPT4000 test system is encased in a durable, stainless steel cover that can be used in the laboratory or alongside manufacturing lines to verify that containers meet packaging industry specifications.

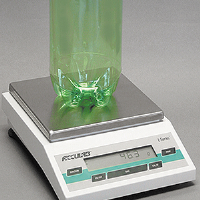

The PPT4000 has the ability to provide up to 400 psi of water pressure to test the properties of various containers with precise control for any desired set-point up to that pressure. The most common application

for the PPT series of test equipment is PET bottle filling simulation where less than 300 psi is typically all that is needed to test the container properties. By combining high-flow prefilling and rapid pressurization, the cycle time of these containers is reduced to under 60 seconds. With it’s unique control and plumbing systems, the PPT4000 offers enhanced testing throughput, accuracy and reliability.

Valuable process tool for PET container production

The PPT4000 is a critical process tool for the management of PET container production, given the relationship of volume expansion to key container performance variables including creep, gas permeation, burst, stress cracks, rigidity, bottom roll-out, topload and thermal stability. The PPT4000 provides 13 second and optional user-defined volume expansion points that enable operators to configure the duration of time for capturing volume expansion during testing. This feature makes it possible to precisely simulate actual filling conditions and how the bottle will perform under those conditions.

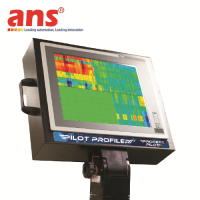

Easy-to-use operator interface

The PPT4000 pressure tester features a large, touch-screen display that is the center for operator interaction and presentation of on-going test data. All functions of the testing system are managed from this ergonomically designed user interface.

- Adjustable touch screen operation

- Easy navigation

- Graphic display of test curves

- Easy access to result history

- Test parameters display

- Mold number input

- Alarm and maintenance log

- Ability to input post-test comments