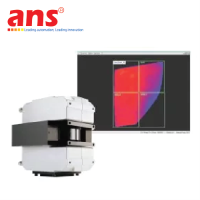

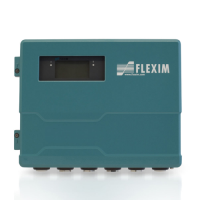

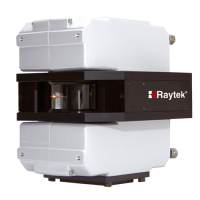

Glass Process Imaging System RAYTGS150G5R0 Raytek

Price: Contact

Brand: Raytek

Category: Thiết bị đo lường & Kiểm tra

Supplier: ansvietnam

Origin: USA

Glass Process Imaging System RAYTGS150G5R0 Raytek

Fluke Process RAYTGS150G5R0 Offers

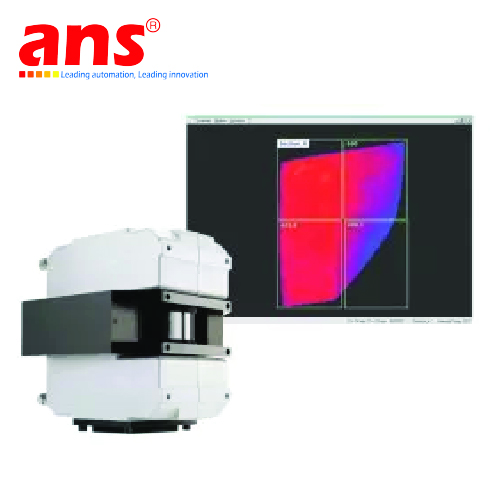

The GS150 measures a line of up to 1024 points using a rotating mirror that scans a 90º field-of-view up to 150 times per second. The scanning of a glass part is initiated by the measured temperature, or an external "trigger" signal. As each heated glass part traverses the field-of-view, a two-dimensional thermal image or "thermogram" is formed.

Installs easily, just like a camera, and views the glass part from above, whenever it has a clear path. Connecting the pre-wired cables (included) to a PC and entering installation dimensions in the GS150 Software completes the installation process.

Features

- Improve profitability and product quality

- Reduce setup time and detect defects quickly

- Define product-specific configurations and data files

- Automate quality monitoring for ISO9000

- View complete thermal images and temperature profiles

- Customize and display zones overlaid on a thermal image

- Automatically analyze zone temperatures

- Viewing of complete thermal images and temperature profiles

- Thermal image "snapshot" by the temperature or by an external trigger

- Automatic analysis of zone temperature distributions (minimum, maximum, average, gradient, etc.)

- Fail-safe alarm logging

- Defined product-specific configurations

- Event-based saving of thermal images with archive function for analyzing temperature data

- Easy connection with existing visualization and control systems via flexible system interfaces: OPC or DDE, analog or digital output modules, serial RS232 port, Ethernet

Top Applications

This application involves the forming of automotive and truck/bus windshields in the sag-bending process. The glass sheet is heated until it is within it's viscoelastic phase, at which point, the glass then slumps into a former to take on the required shape.

This application involves the forming of automotive and truck/bus windshields in the sag-bending process. The glass sheet is heated until it is within it's viscoelastic phase, at which point, the glass then slumps into a former to take on the required shape.