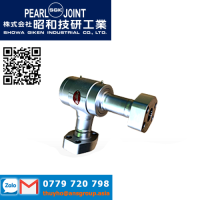

Measuring LIMAX2M-20-CON-0500-CO1TG-M12M ELGO Electronic

Price: Contact

Brand: ELGO Electronic

Category: Thiết bị đo lường & Kiểm tra

Supplier: ansvietnam

Origin: Germany

Measuring LIMAX2M-20-CON-0500-CO1TG-M12M ELGO Electronic

Absolute Measurement for Elevator Heights up to 130 m

-

Resolution: 62.5 / 125 / 250 / 500 or 1000 μm

-

Highly Resistant to dust, smoke, and humidity

-

Travel Speed: Up to 4 m/s

-

Multiple Interfaces available

-

No Reference Run Required

-

Easy and Flexible Installation

-

Vertical Magnetic Tape Mounting

-

Non-contact, Wear-free, and Silent Measurement Principle

Overview

The LIMAX2M NEO Absolute Shaft Information System offers outstanding performance, providing a cost-efficient, robust, and easy-to-install alternative to conventional shaft information systems. Thanks to its absolute measuring principle, there is no need for a reference run after commissioning.

With a measuring range of up to 130 meters and speeds reaching 4 m/s, the LIMAX2M NEO is designed for both new installations and modernization projects. The "2M" in its name stands for "Mini", indicating the smallest sensor design in the LIMAX2 series, while "NEO" denotes the new generation. Its compact size makes it ideal for retrofitting into existing elevator systems with limited space.

The simplified and flexible installation process ensures quick setup or replacement of the measurement system, minimizing downtime.

Magnetic Tape

To measure the elevator position, the sensor uses an AB20-80-10-1-R-D-15-BK80 absolute encoded magnetic tape, which carries unique position data in the form of magnetic coding. This tape is suspended freely inside the elevator shaft using ELGO mounting brackets (see accessories section).

At the bottom end, the magnetic tape is tensioned and guided alongside the cabin using a plastic guide rail at the sensor. The actual measurement and scanning process is contactless, with the guide rail only ensuring the correct distance between the sensor and the tape.