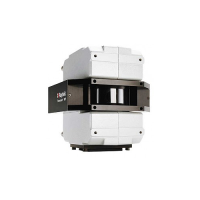

CS400 Kiln Shell Imaging System

Price: Contact

Brand: Fluke Process Instruments Vietnam

Category: Thiết bị đo lường & Kiểm tra

Supplier: ANS Vietnam

Origin:

Ứng dụng sản phẩm: Automotive

Fluke Vietnam,CS400 Kiln Shell Imaging System

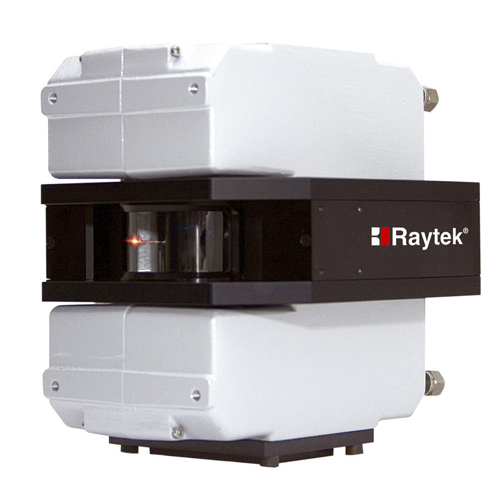

CS400 Kiln Shell Imaging System

CS400 Provides Complete Kiln Monitoring

Capability

Kiln shell temperatures are monitored along the entire length of the kiln,

providing an essential indication of the health of the refractory material.

Temperature data for areas “shadowed” from the main sensor can be

provided by individual point sensors and seamlessly integrated into

one complete thermal image. Optional burning zone sensor and tire slip

monitoring can be integrated into the system, so that all information is

displayed on one screen in the control room. All events, as well as kiln

and refractory data, can be viewed in an optional real time moving 3D

view. These events can be permanently linked in an extremely versatile

Refractory Management database.

Rugged & Reliable for

Continuous Kiln Shell Monitoring

Picture every brick in your kiln in real-time with continuous infrared

monitoring that can help prevent costly shutdowns and extend production

runs. Specifically designed for harsh kiln environments, the CS400

Process Imaging System is a fully integrated solution that continuously

monitors kilns for hot spots – helping your team avoid costly damage and

unscheduled downtime.

At the core of the CS400 System is the MP Linescanner, which provides

accurate, edge-to-edge and real-time thermal imaging and temperature

measurements for continuous processes so you can get a complete picture

of your application.

To ensure reliable operation in

hars kiln environments, the MP

linescanner is designed with rugged,

aluminum-cast housing, which in

turn is mounted in a robust stainless

steel protective housing with

provisions for air-purge and water

cooling.

The protective housing includes an

adjustable mounting bracket to aim

the scanner along the kiln axis, a

mounting rail permitting fast scanner

installation, quick-disconnect fittings

for air purge and water cooling and

an easily replaced viewing window |

Kiln Shell Scanning System

Specifically designed for kiln monitoring, the CS400

is a fully integrated solution that monitors rotary kilns

to detect hot spots while avoiding costly damage and

unscheduled downtime. Optional, yet fully-integrated,

accessories, extend the CS400’s capabilities to include

shadow sensing, burn zone monitoring, tire slip and

fan control.

At the core of the CS400 system is the MP150

linescanner , which can scan up to 1024 data points

in a single scan, and an integral heater that can

be configured specifically for users’ unique kiln

applications. As an option, the system profiles a fully

featured Refractory Management data base.

Rotary Kiln Applications

• Cement Kilns

• Lime Kilns

• Metals and Chemical Processing

Benefits

• Detect hot spots due to refractory loss,

damage or wear

• Detect abnormal operating conditions such as

faulty flame position and shape

• Optimize and manage kiln maintenance

• Extend operational life of kiln

and refractory

• Completely integrated monitoring

of key kiln parameters

Features

• Map entire kiln surface and display in real-time

thermogram format

• “One brick” resolution hot spot detection,

even in shadowed areas

• Fail-Safe “hot spot” alarm outputs

(PC independent)

• On board Ethernet TCP/IP communication

• Interface with other programs via OPC

• Refractory Management software

• Modular design simplifies installation and

service

• All data, alarms and errors stored and

accessible in one common database

• Multiple level security settings

• Multiple Scanner Support

• Real time 3D view of the kiln

• Refractory Management

Accessories

• Tire Slip Monitoring

• Fan Control

• Burning Zone Monitor Package

• Shadow Sensor Package

CS400 System Software

User Friendly Software Provides Easy

Configuration and Startup

The CS400 Kiln Shell Imaging System features specially designed

software, which relies on standard Ethernet and/or CPM ports.

Because the graphic user interface is designed specifically for

kiln applications, the software is easy to set up and use with

little operator training required. With a variety of options and

accessories, the CS400 system expands to become a comprehensive

kiln monitoring tool.

Rapid Set up

Using intuitive set up screens, operators can easily enter the kiln’s

physical dimensions and linescanner position. Once established,

the software displays the resulting configuration and manages

temperature profile calculations.

Integrated Shadow Monitoring

Point sensors can be quickly configured to cover any shadow areas

created by the tires or by physical obstructions, such as buildings or

utility poles. All sensors are configured from one screen and, since

the software senses any conflicts and notifies the operator, set up

errors are virtually eliminated.

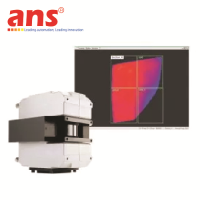

Kiln Shell Thermal Image

The software provides a thermal image of the entire kiln shell

surface, with a zoom function that allows detailed examination of

areas of interest. Temperature range, color palettes and zone alarms

are easily configured within the user-friendly software. Other

useful information, such as burning zone temperature, lap time and

the scanner’s internal temperature, is displayed in the status bar to

provide a complete system status without changing screens

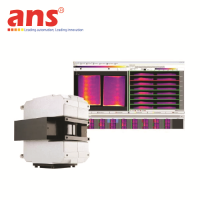

Historical Data Analysis

Kiln shell temperature snapshots are taken at user-defined intervals

and stored in both short-term and long-term databases for later

review. Data can be viewed as thermograms, histograms or as line

charts to monitor gradual refractory degradation or other changes.

Integrated Live Ring Migration

Proximity sensors measure the rotation of each tire and calculate

the tire slip at each location. Results are calculated and displayed

for each rotation as well as being stored for data analysis. Any

deviation beyond user-defined limits results in immediate alarms.

CS400 System Accessories

Tire Slip Monitoring (TSM)

The TSM sensors and connection boxes required to activate

the system can be purchased as an accessory. This system

records tire slip and can be configured to generate alarms

at user-defined limits. The TSM is fully integrated with the

system software and is capable of extensive historical data

analysis.

Fan Control

Fan control software is included with the CS software to control

up to 48 discrete zones. The optional fan control hardware allows

the user to provide outputs to up to 16 fans per module.

Burning Zone Monitor Kit

When the optional Burning Zone Monitor Kit is installed,

operators can monitor the condition of the critical burning

zone area directly using the CS software. Temperature is

displayed alongside the kiln shell temperature and all data

is recorded and date stamped for later analysis. The kit

consists of a two-color ratio point sensor to “see through”

the combustion gases, a protective housing and all of the

hardware needed to complete the installation.

Shadow Monitoring Kit

The CS software can accommodate select pyrometers from

Fluke Process Instruments to monitor areas of the kiln

shadowed from the main linescanner. The data is seamlessly

integrated into a single thermogram, both for real-time

display and for later data analysis. For convenience, the most

commonly used sensor and all of the necessary accessories

are provided as a kit.

Refractory Management Kit

The Refractory Management Module Database is based on

an enhanced data management system that can monitor the

installed brick, including gathering, storing and analyzing all

necessary data to indicate refractory wear during use.

The content of the database will be related to the kiln

and refractory. Examples of this input data are: time of last

maintenance, brick types and properties, brick/refractory

zone names and positions, as well as flame/burning zone

temperature (with optional hardware).

The software features easy user interface for entering

standard data with predefined dropdown lists, as well as easy

to use history tracking that includes all related refractory and

kiln data, maintenance data, date, time and record of changes

made by user name.

The Refractory Management Module will help cement

manufacturers and rotary kiln operators decide

when to change the refractory of a cement kiln.

3D View

The 3D view module will help to easily understand all the

data from the kiln and its environment, including life view

of the rotating kiln, life rings and zones (with optional

hardware), even for the non-refractory related “real-time

view”, which is part of the standard CS System

Specifications

Temperature range 100 to 650 °C

Temperature resolution 0.1 K

Accuracy ± 0.5% of reading or ± 3 °C

Spot detection 450 : 1 ( 2.2 mradians )

(50% of energy)

Sampling rate 1024 pixel per scan line

(2048 for CS402)

Scan motor MTBF: 40,000 hours

Ambient operating temp. -40 to 45 °C ( no direct sunlight )

Position indicator temp. -25 to 230ºC

Zone alarms 48 software, 3 hardware (PC

independant)

Kiln rotation rate Up to 10 rpm

LRM accessory Supports up to 6 tires

Fan Control accessory Supports up to 16 fans per

module (48 total)

Burning Zone Accessory MR Ratio Pyrometer 700 to

1800 °C, connection box, 15 m

high temp. cable, Thermojacket,

blast gate, sighting tube, adj.

pipe adapter, adj. mounting base,

air flow/press. regulator

Shadow Monitor Accessory MIH Sensor (-40 to 600 °C) with

8 m high temp. cable, air purge

jacket and adj. mounting

CS400 System Details

Linescanner MP150 linescanner (2 for

CS400)

(includes all required cables

and connectors)

Protective Housing Rugged Stainless Steel

Housing (2 for CS402)

System Connection Box 2 for CS402

Position Indicator High-temperature kiln

rotation sensor

Software CS400 System Software

Documentation Documentation Binder with

Operators Manual and MP

Manual

Startup Service On-site startup

commissioning/training

available

CS400 Part Numbers

CS401-MP150-KIT CS400 Kiln Shell Monitoring System

CS402-MP150-KIT-2 Dual scanner system for longer kilns

CS403-MP150-KIT-3 CS403 Rotating Kiln System (3 scanner system)

CS404-MP150-KIT-4 CS404 Rotating Kiln System (4 scanner system)

A-CS-CONV-ETH485 Serial RS485 / RJ45 Ethernet Converter

(req’d for accessories)

A-CS-TSM-KIT-485 Tire Slip Monitoring (TSM) Hardware Kit

A-CS-BZ-EN-KIT-485 Burning Zone Monitor Kit

A-CS-SM-KIT-485 Shadow Monitor Kit

CS400-SW-CS210-UPG Basic upgrade from old CS210

Easy Installation & Maintenance

The MP150 linescanner (1) is installed to view the desired portion of the

kiln. The Position Indicator (2) is a high-temperature inductive sensor that

synchronizes thermal imaging with kiln rotation. The System Connection

Box (3) provides for local cable/wire termination. The Interface Box (4)

connects the scanner to the PC (5) and contains fibre-optics to Ethernet

conversion. The scanner communicates to a PC via fibre-optics for

distances up to 2000 m.

CS400 System components are easy to install and are field-replaceable.

When installing two linescanners, they may each mount at different

angles so that each has a clear view of the kiln shell. CS software

combines the data from each scanner providing a single thermal image for

display and analysis.

The CS400 System installs in a standard PC (local operating system) without

need to add expansion cards or open the computer.

=====================================================

Đại lý phân phối chính hãng Fluke tại Vietnam

Báo giá ngay – Hàng chính hãng – Bảo hành 12 tháng – Tư vấn hỗ trợ kỹ thuật 24/7

Xem thêm sản phẩm hãng Fluke tại đây

Xem thêm thông tin về thương hiệu khác tại đây

Xem thêm sản phẩm khác tại đây