Mehrer máy nén lạnh TZW 50, TZW 60, TZW 70 Mehrer

Price: Contact

Brand: Mehrer Vietnam

Category: 4.0 Industry

Supplier: ANS Vietnam

Origin:

Ứng dụng sản phẩm: Automotive

ABOUT MEHRER:

As a Swabian company in mechanical engineering, our cornerstones are precision and innovation combined with a lot of commitment and passion. Decades ago we did pioneering work with our dry-running compressors in cross-head design and are the world's leading manufacturer of oil-free reciprocating and diaphragm compressors. Today we use our many years of know-how in dealing with a wide variety of gases in order to offer sophisticated solutions for your special application down to the last detail.

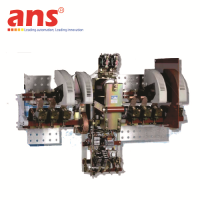

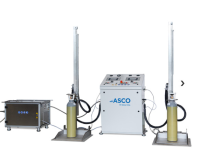

TWO-STAGE, WATER-COOLED COMPRESSORS MEH - MÁY NÉN LẠNH MEHRER:

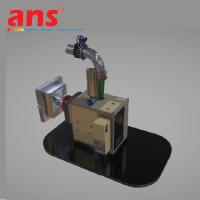

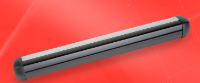

TZW 50, TZW 60, TZW 70 Máy nén Mehrer - Compressors Mehrer TZW

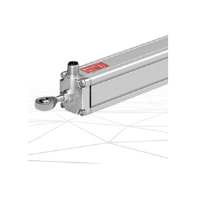

TZW 50, TZW 60 and TZW 70 are two-stage, water-cooled compressors. These products are used in the sectors Food & Beverage as well as Machine Construction and are developed for all oil- and silicone- free applications. Mehrer’s vertical compressor design is space saving. The TZW 50, TZW 60 and TZW 70 Mehrer can be operated with pre-pressure and frequency controlled working speed.

The most important advantages:

• 100 % oil-free compression without the use of filters

• Water-cooled

• Low maintenance

• Durable

• Efficient

• Robust

• Risk assessment according to DIN EN ISO 12100

Technical data Compresor Mehrer - Máy nén lạnh Mehrer TZW:

|

Model series Features |

TZW 50 2-stage, single-acting |

TZW 60 2-stage, single-acting |

TZW 70 2-stage, double-acting |

|

Max. compression ratio per stage |

1 : 5.5 |

1 : 5.5 |

1 : 5.5 |

|

Max. suction pressure |

9 bara |

9 bara |

9 bara |

|

Max. final pressure* |

27 bara |

23 bara |

23 bara |

|

Stroke volume per 1 crank revolution |

3 604 ccm |

6 652 ccm |

11 426 ccm |

|

Max. drive power on the shaft |

15 kW |

37 kW |

55 kW |

|

Speed range |

400 - 710 rpm |

380 - 725 rpm |

380 - 725 rpm |

|

Arrangement of the cylinders |

Series |

Series |

Series |

|

Type of drive |

Belt driven |

Belt driven |

Belt driven |

|

Compression of toxic and flammable gases |

Possible |

Possible |

Possible |

|

Compressor cooling |

Water-cooled |

Water-cooled |

Water-cooled |

* Relieve pressure safety valve, operating pressure max. = 0,9 x max. final pressure

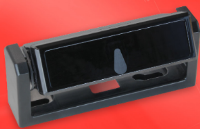

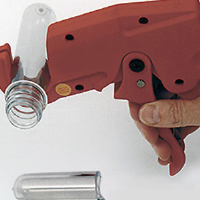

- CYLINDER BLOCK: Due to the modular design of the cylinder block, the compressor can be adapted according to its compression requirements.

- LANTERN: The lantern is the key to oil-free compression.

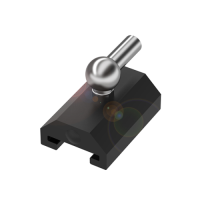

- CRANK GEAR: Our extremely robust crank gear ensures high availability of the system through the crosshead design.

- GAS GLAND: This assembly separates the gas section of the compressor from the drive section. It prevents gas from the compression space from getting into the lantern. The gas gland is designed according to the application.

- LEAKAGE AND PURGE GAS CONNECTIONS: Due to the built-in connections, the compressor can be purged with inert gases. This allows also corrosive gases (e.g. high H2S content) to be compressed.

Xem thêm nhiều sản phẩm Mehrer tại đây!

Liên hệ ngay với chúng tôi để biết thêm thông tin về sản phẩm Mehrer máy nén lanh Mehrer

Hotline: 0911 47 22 55

Email: online@ansgroup.asia