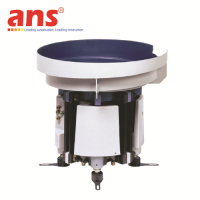

Rollers SS-CRM-MP-33 RULMECA Vietnam

Price: Contact

Brand: Rulmeca

Category: 4.0 Industry

Supplier: ansvietnam

Origin: Italy

Rollers SS-CRM-MP-33 RULMECA Vietnam

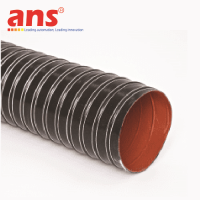

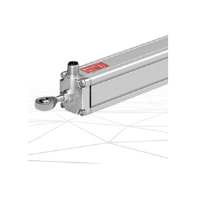

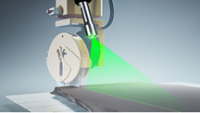

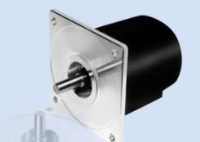

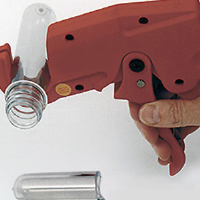

Our impact rollers, or shock absorbing rollers, are built with a durable steel roller base and enhanced with impact-resistant rings. These rings are designed to absorb and manage the stresses from materials hitting the conveyor belt. Located in the belt's carrying section, these rollers are aligned with the loading points where materials make contact. The addition of thick, resilient rubber rings ensures that the impact forces are adequately absorbed, protecting both the rollers and the belt from potential damage caused by heavy or uneven material loads.

Solid Rubber Rings Fixation by High Steel Stop Ring, Welded to the Shell

The rubber rings on our impact rollers are securely fixed using a high-strength steel stop ring, welded directly to the roller shell. This robust fixation system ensures that the rings remain firmly in place, even under intense impact and heavy material loads. The welded steel stop ring provides additional stability, preventing the rings from shifting or detaching during operation. This design guarantees the reliable performance of the impact roller, reducing the need for maintenance and increasing the overall durability of the roller system