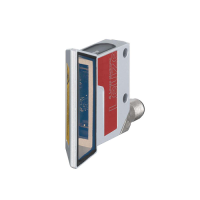

Photoelectric sensor receiver LE55CI.H2O/4P-200-M12 Leuze Vietnam

Price: Contact

Brand: Leuze

Category: 4.0 Industry

Supplier: ansvietnam

Origin: USA

Photoelectric sensor receiver LE55CI.H2O/4P-200-M12 Leuze Vietnam

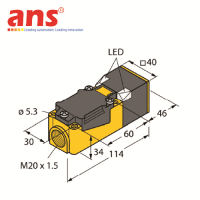

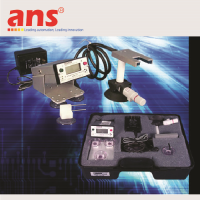

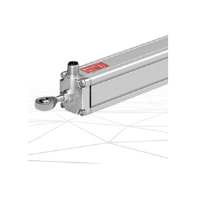

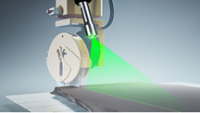

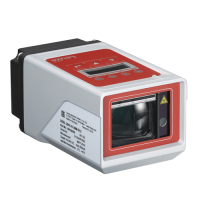

Leuze LE55CI.H2O/4P-200-M12 – Rugged Through-Beam Photoelectric Sensor for Harsh Environments

The Leuze LE55CI.H2O/4P-200-M12 is a high-performance through-beam photoelectric sensor receiver designed for reliable object detection even in challenging conditions. With stainless steel housing, M12 connector, up to 200 mm installation depth, and full wash-down compatibility, it works superbly in industrial automation, packaging, food & beverage, and wet environments.

🔧 Key Features

-

Through-beam principle (receiver unit) with a large operating range up to 0–64 m and guaranteed up to 0–200 mm installation depth for aqueous applications.

-

Stainless steel housing (AISI 316L) and robust lens cover, designed for harsh, wet, or chemical‐exposed environments.

-

Cable connection with M12, 4-pin, and 4-wire, enabling easy plug-and-play mounting.

-

High switching frequency up to ~350 Hz and fast response time ~1.43 ms, ideal for high-speed detection.

-

Wide ambient temperature range from –40 °C to +70 °C, with protection rating IP67 / IP68 / IP69K for extreme water, dust and cleaning conditions.

✅ Benefits for Your System

-

Reliable detection in wet/harsh environments: The rugged stainless steel build and high ingress protection mean this sensor can thrive in food processing, beverage, outdoor or wash-down applications.

-

High performance at speed: With fast response and high switching frequency, the LE55CI.H2O/4P-200-M12 performs in fast conveyor and packaging systems.

-

Flexible mounting & wiring: M12 connector and compact design simplify installation and reduce downtime.

-

Long service life & lower maintenance costs: Robust materials and protection ratings improve durability and reduce replacement/repair costs.

-

Operational stability: Wide temperature range allows deployment in both refrigeration and hot production zones.

🎯 Typical Applications

-

Beverage and food production lines where sensors may be exposed to wash-down, water splashes or cleaning chemicals.

-

Packaging systems with fast conveyors that require rapid and consistent object detection.

-

Outdoor automation or logistics equipment exposed to dust, water jets or high humidity.

-

Industrial machine tools, robotics or assembly stations requiring rugged sensing in tough conditions.