Air cooled chillers TAEevo TECH MTA S.P.A Vietnam

Price: Contact

Brand: AIC Vietnam

Category: 4.0 Industry

Supplier: ansvietnam

Origin: Italy

Air cooled chillers TAEevo TECH MTA S.P.A Vietnam

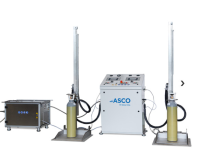

Air cooled chillers.

Nominal cooling capacity 8 - 259 kW

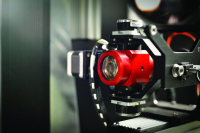

The TAEevo TECH chillers are compact units designed for use in industry, supplied with hermetic scroll compressors and the innovative finned pack evaporator installed inside the hydraulic storage tank.

The dual - frequency version integrates the already wide technical equipment of the standard unit, well suited to guarantee a secure and repeatable production process, while saving you money and protecting the environment.

Thanks to the wide operating limits, it can operate in pressurized hydraulic circuits or at atmospheric pressure and thanks to the many versions and optionals available, the TAEevo TECH chillers are the top of their category, allowing great application versatility and high degree of reliability. TAEevo TECH is therefore the best solution for all process applications that require high performance, continuous operation and reduction of management costs.

Technical features

| Mode | Compressors | Refrigerant | Heat exchanger | Fan |

|

|

R410A |  |

|

Benefits:

- The refrigerant R410A (ODP=0) ensures high performance thanks its outstanding heat conductivity properties;

- Innovative evaporator with immersed finned coil, characterized by low pressure drops and reduced sensitivity to impurities;

- The oversized hydraulic tank is standard and is able to compensate for the imbalances caused by sudden changes in load demand from the user;

- Wide operating limits (Minimum Twout = -10°C standard);

- Hydralic circuit adaptable for atmospheric and pressurized hydraulic circuits (up to 6 barg);

- Compact structure;

- Suitable for outdoor installation;

- Standard air condenser filters;

- Safety hydraulic by-pass;

- Wide range of accessories and kits for customized solutions;

- Easy installation, use and maintenance;

- Designed to operate 24/7 under the most demanding industrial conditions;

- Master/slave modularity from 2 to 5 units.

Technical features:

- Galvanized carbon steel sheet structure hot painted with polyester powders;

- Refrigerant: R410A;

- Parametric microprocessor controller;

- High performance hermetic scroll compressors;

- Immersed finned coil evaporator with copper pipes and aluminum fins inside inertial tank;

- Finned condenser coil with copper pipes and large aluminum fins protected by filters;

- Electronic expansion valve (from mod.031);

- HP/LP refrigerant manometers (from mod.031);

- Integrated hydraulic circuit configuration made up from: single or double circulation pumps with medium or high available head pressure, inertial tank, safety valve, air vent valve;

- Water flow pressure manometer;

- Phase monitor;

- Crankcase heater compressor;

- Axial fans with optimized profile;

- Conductive level sensor;

- Electric power supply 400/3/50;

- SEPR HT and SEPR MT Tier2 compliant.

Versions:

- Pressurized Non Ferrous hydraulic circuit (mod.020-802);

- Close control regulation of the outlet water temprature through hot gas by-pass valve (hysteresis ± 0,5°C) (mod.020-351);

- Low ambient temperature version up to -20 °C mod. (031- 1002);

- Dual frequency version: power supply 400V/3/50 Hz - 460V/3/60 Hz (mod.020-161);

- UL508A - CSA 22.2-14 version: power supply 460V/3/60Hz.

Accessories:

- Evaporator anti-freeze protection;

- Single or double circulation pumps (mod.201-1002) with medium or high available head pressure;

- Open circuit circulation pump with medium available head pressure (mod.031-1002);

- Without pump version;

- Centrifugal fans (mod.031-161);

- High efficiency EC brushless axial fans with high head pressure (max 150 Pa) and inverter control (mod. 201-802);

- Electronic fans speed regulation (mod.031-802);

- EC brushless fans (mod.902-1002);

- Condensing coils protection with protective paint.

Kit:

- Manual filling kit for atmospheric hydraulic circuits;

- Automatic filling kit for pressurized hydraulic circuits;

- Glycol filling kit for pressurized circuits;

- BSP-NPT hydraulic fittings;

- Automatic hydraulic by-pass;

- Centrifugal fans;

- Electronic fans speed regulation kit;

- Remote ON/OFF;

- Remote display;

- Supervisor system RS485, XWEB300D EVO;

- Master/slave modularity kit from 2 to 5 units.